Projects

Case studies

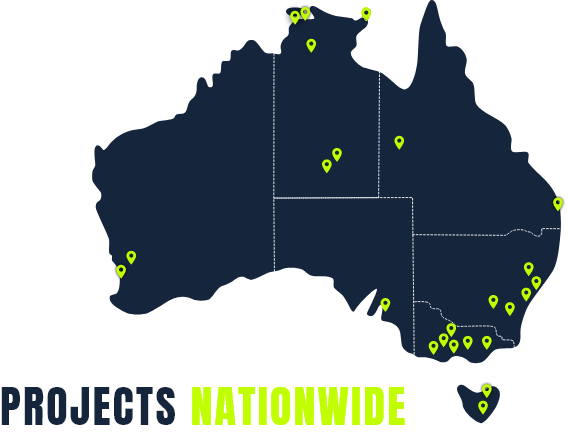

Projects

Other Recent Projects

611 Elizabeth Street

Supply and installation of 220KVA generator with fuel reticulation system.

Caterpillar Training Centre

Installation of G3512 generator used for training generator technicians with set-up and commissioning.

Queen and Collins

Upgrades to generator control system for 3 x 1500KVA generators.

Woolworths Distribution Centre

Installation of acoustic canopy, exhaust, fuel and cooling system for 2 x 2000KVA generators.

Sky Gardens

Installation of exhaust system for fire pumps.

Melbourne Airport Hotel

Supply and installation of 1000KVA generator complete with acoustic enclosure, fuel system and generator controls.

720 Bourke Street

Upgrade to bulk fuel storage system including supply and installation of 2 x 15,000L Drac Defender Tanks.

Bombardier Auxilliary Generator System

13-off generator housing frames complete with jacket water / charge air cooling system piping for V-Line N Series BRN train carriage

George Weston Foods

Replacement of 2000KVA gas generator set complete with exhaust and cooling system upgrades.

Melbourne Air Traffic Service Centre

Installation of fuel system to service 4 x 2250KVA generators including control system and 2 x 17,000L Drac Defender Tanks.

Equinix Data Centre

Supply and installation of fuel, exhaust, acoustic/air handling, fuel controls for 2 x 2500KVA generators and 5 further future units.

BCG (Boral) Geelong

Installation of underground gas mains to service 3 x burners.

308 Exhibition Street

Installation of 2500KVA generator complete with generator and fuel controls, fuel, air handling, acoustic and exhaust systems.

Scape Living

Installation of fuel, acoustic and exhaust system for 1 x 1100KVA generator.

West Side Place

Installation of 2 x 1100KVA generators complete with fuel, air handling, acoustic and exhaust systems.

Melbourne Connect

Installation of 1650KVA generator complete with generator and fuel controls, fuel, air handling, acoustic and exhaust systems.

Brushy Creek

Installation and upgrade of existing generator including supply of acoustic enclosure package complete with integrated fuel and exhaust system.

Chep Derrimut

Installation of 2 x boilers complete with mechanical and electrical connections to feed steam to new washer.

Bairnsdale Regional Health

Installation of 2 x generators complete with fuel, exhaust and acoustic systems.

Cabrini Hospital – Gandel Wing

Extension of existing generator exhaust system through new building wing and integration with existing generator systems.

150 Lonsdale Street

Installation of 600kVA generator complete with fuel system, fuel control system, generator control system, acoustic enclosure complete with exhaust system.

Raheen House

Installation of generator and associated fuel transfer system including fabrication of 20,000 litre fuel storage tank.

Junee Correctional

Installation of x 2 1100KVA generators including fabrication of 40,000 litre fuel storage tank, fuel reticulation system and exhaust system.

Adelaide Produce Market

Installation of 3000KVA HV generator within acoustic enclosure with integral fuel, exhaust and air handling system.

Australian Tallow

Provide upgrade works for boiler systems to achieve various heat recovery and economising targets.

485 Latrobe Street

Installation of 1 x 1100KVA diesel generator including acoustic air handling, fuel reticulation and exhaust system. Exhaust system retrofitted to building façade using rope access installers.

664 Collins Street

Installation of generators complete with fuel reticulation system.

Rod Laver Arena Redevelopment

Installation of acoustic louvres and attenuator to the new plantrooms associated with the redevelopment works.

Regional Landfill Mechanical Upfit

Provide fuel gas, lube oil and cooling system package for 4 x 2500KVA gas generators.

Collins Square Tower 5 – Stage 2

Installation of 1 x 1100KVA standby diesel generator to provide back-up power in the event of building mains power failure.

Australian Glass Group

Installation of acoustic enclosure and attenuators over their glass processing plant within their new facility.

Werribee Mercy Hospital

Installation of 1 x 1100KVA diesel generator mounted in acoustic canopy with fuel reticulation system.

Northern Hospital

Replacement of 2 x 1400 KW hot water boilers & replacement of 2 heat exchangers.

Australia 108

Installation of 1 x 1100KVA diesel generator on level 12 plant room including acoustic air handling, fuel reticulation and exhaust system. Underground services including 3,000L bulk fuel storage tank.

Collins Square Tower 4

Installation of 1 x 1250KVA and 1 x 1650KVA diesel generators on level 21 plant room including acoustic air handling, fuel reticulation and exhaust system.

Collins Square Tower 5 – Stage 1

Installation of fuel reticulation system for future generator installation including installation of 30,000L bulk fuel storage tank and transfer pump system.

Riverside Quay

Installation of 2 x 560KVA diesel generators. One generator on level 9 and one generator on level 21. Includes acoustic air handling, fuel reticulation and exhaust systems.

Fonterra (Stanhope)

Installation of various acoustic devices to achieve EPA standards compliance.

The Valley Private Hospital

Installation of 1 x 2250KVA diesel generator including acoustic air handling, fuel reticulation and exhaust system. Underground services including 10,000L bulk fuel storage tank.

Latrobe Valley Hospital

Fuel system upgrade works for 1 x 400KVA generator.

Parliament Square (Hobart)

Mechanical installation of 1000KVA generator in custom (build on site) acoustic canopy on level 9.

Chifley South Enabling Work

Project in progress.

Gatton Prison

Supply and install acoustic enclosure with remote radiator for CAT 3512B.

Centres for National Resilience Brisbane

Installation of 2 x 1MVA prime rated generators, 5000L base tanks and acoustic enclosures.

Phosphate Hill Mine site

Provide upgrade works for fertiliser rail load out PLC batching system.

Yulara Hybrid Power Station

Design and fabrication four (4) off acoustic enclosures for CAT 3512B generators.

Arnham Space Centre

Supply and installation of remote monitoring system for 2 x Standby generators, including fabrication of 60,000L bulk fuel storage tank and fuel reticulation system.

Charles Darwin University

Supply and install 1 x 550kVA Generator.

Equinex Perth

ME2 is an expansion to the Port Melbourne based data centre facility owned and operated by Equinix – a leader in the global colocation data centre market share.Drac were contracted for the installation of 2 x Cummins 3000kVA diesel generators with fuel reticulation system and controls, exhaust and acoustic/air handling systems to service 7 x future generator sets. The project also included the provisional services for the next phases of the ME2 facility. The future phases will see a total 7 x 3000kVA diesel generators in operation.

Centres for National Resilience Perth

Installation of 2 x 1MVA prime rated generators, 5000L base tanks and acoustic enclosures.

83 Pirie Street Adelaide

Supply and installation of standby generator complete with acoustic system, fuel system and generator controls.

Adelaide Festival Square

Supply and installation of 1 x 1400kVA generator complete with acoustic system, fuel system and generator controls.

Sunshine Hospital

Installation of 1 x 1100kVA generator complete with acoustic system, fuel system and generator controls.

Castrol Trade Waste

Install 1 x 1500kW boiler with mechanical and electrical upgrade.

Why Choose Us?

THE DRAC DIFFERENCE

We are the only company in the industry that can provide a true in-house offering. This allows us to control every level of our supply chain. That's why we're the industry leaders in quality and project delivery.

ON-TIME, ON-BUDGET

Our reputation is testimony to on time and on budget projects. We’ve never missed a deadline.

FULLY IN-HOUSE TEAM

We don’t subcontract out any part of the process or system. Everything is handled in-house by our team of experts.

COMMITMENT TO SAFETY

Our Zero harm attitudes ensure that we’re always providing a healthy and safe work environment. We continuously monitor how we can eliminate risks in the workplace.

PEACE OF MIND

Our team of expert engineers and technicians will handle any roadblocks quickly and efficiently. Our customer retention is testimony to this

Clients

Trusted By